“ Designing With

Dichroics “

Page Three

| Most of todays optical design engineers are qualified in MIL spec coating applications while using the latest computer technology available. Layering and substrate masking can make a big difference with regard to the consistency of the end product. A controlled and clean environment is essential. Tits & pits produced by dirt and scratches can weaken the coating. There are several minerals or materials that can be used to produce the same color. Some materials cost less. This can effect the hardness of a coating. Post coating processes can also differ. Coating procedures are a must. Substrate cleaning and handling is always important. Dichroics And How They Work If you remember there are four types of color filters used to produce colored light. Dyed polyester gel, tinted or resin or Lexan coated glass and dichroic coatings on glass. |

| Off Axis Tweaking

In the process of creating a color separation mirror we are also able to tweak or pivot the mirror off of a O° axis (or normal incidence) and create other colors.

For example: When tweaking a dark blue dichroic at approximately 22° we get a lavender, tweak to 80° you get a flesh pink. |

|

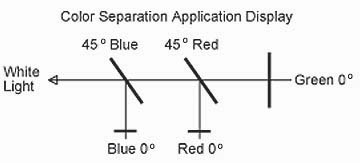

We can also produce color and white light by adding and subtracting light with dichroic filters. A total of five filters would be used. Additive colors (#1) green, (#2) red and (#3) blue. Each additive filter to have a source of its own at 0°. Reflective colors would be (#4) red reflector at 45° and (#5) blue reflector at 45° . NOTE: The blue reflector equals a yellow transmitting filter at 0° and the red (or magenta) reflector equals a blue green transmitting filter at 0°. |

|

| NOTE: The yellow green reflector equals a dark purple transmitting filter at 0° and blue reflector equals an amber transmitting filter at 0°. (example not shown) Color Separation Application Display Green 0° Red 0° Red 45° Blue 45° Blue 0° LightWhite | |

Copyright 1998/1999/2000/2001/2002/2003/2004/2005 Automated Entertainment